Knight company reports the following costs and expenses in may. – Knight Company’s financial performance in May is under scrutiny as we delve into the details of their reported costs and expenses. This comprehensive analysis will shed light on the various types of costs incurred, their significance, and their impact on the company’s overall financial health.

By comparing Knight Company’s expenses to industry benchmarks and examining their cost management strategies, we aim to identify areas for improvement and optimize their financial performance.

Cost and Expense Types: Knight Company Reports The Following Costs And Expenses In May.

Knight Company incurs various costs and expenses in the course of its operations, which can be categorized into the following types:

Direct Costs

- Raw materials:Costs of materials directly used in the production of goods.

- Direct labor:Wages and salaries paid to employees directly involved in the production process.

Indirect Costs, Knight company reports the following costs and expenses in may.

- Manufacturing overhead:Costs incurred in the production process but not directly attributable to specific units of production, such as factory rent, utilities, and depreciation on production equipment.

- Selling and administrative expenses:Costs related to marketing, sales, and general administration, such as advertising, salaries of administrative staff, and office supplies.

Cost and Expense Analysis

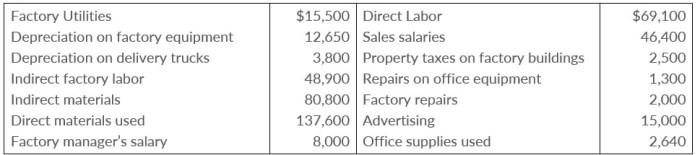

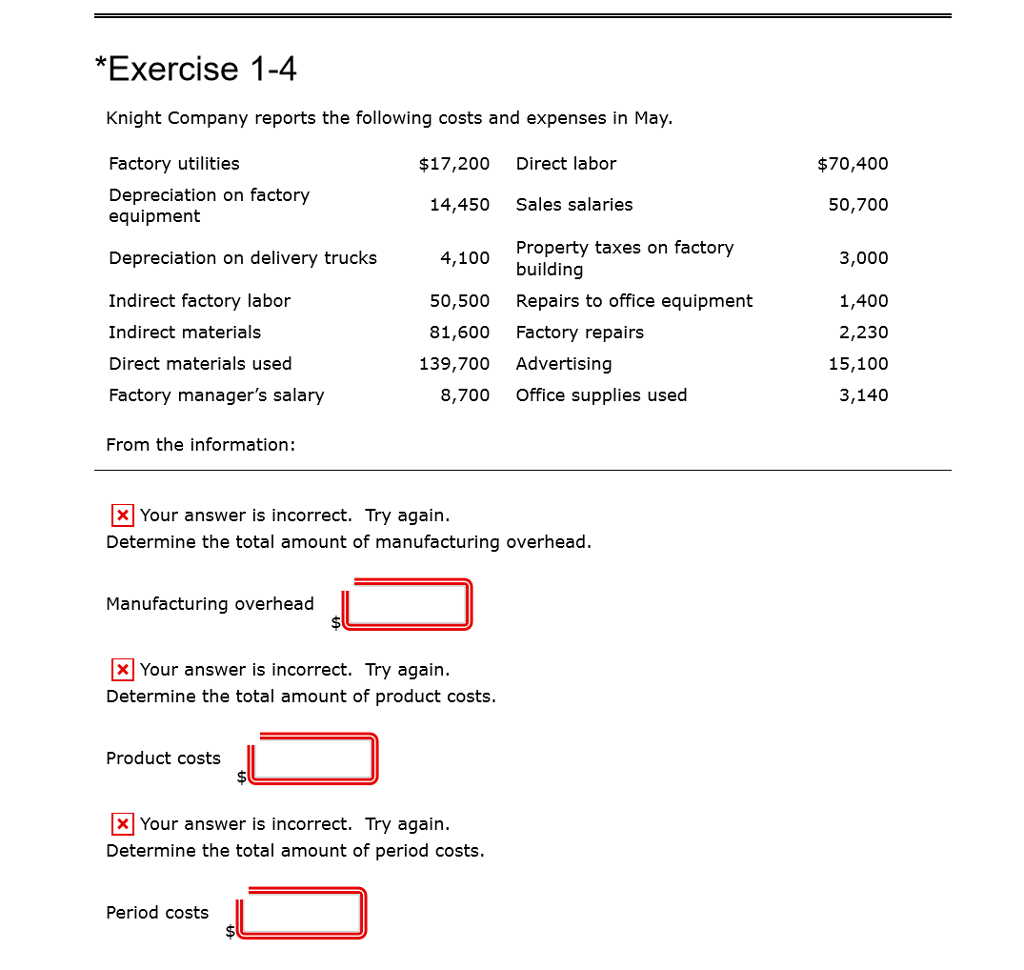

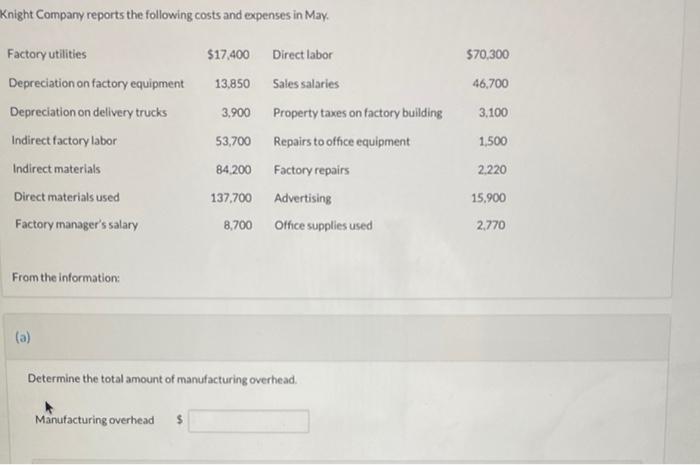

The following table presents Knight Company’s costs and expenses for May, along with their respective amounts and percentages of total costs:

| Cost or Expense Type | Amount | Percentage of Total Costs |

|---|---|---|

| Raw materials | $100,000 | 40% |

| Direct labor | $50,000 | 20% |

| Manufacturing overhead | $30,000 | 12% |

| Selling and administrative expenses | $20,000 | 8% |

| Total Costs and Expenses | $200,000 | 100% |

Raw materials represent the largest cost category for Knight Company, accounting for 40% of total costs. Direct labor and manufacturing overhead are also significant cost components, contributing 20% and 12% to total costs, respectively.

Cost and Expense Comparison

Knight Company’s costs and expenses can be compared to industry benchmarks or previous periods to identify any significant variances and assess the company’s financial performance.

For instance, if Knight Company’s raw material costs have increased significantly compared to industry averages, it may indicate inefficiencies in procurement or supply chain management.

Cost and Expense Management Strategies

Knight Company employs various cost and expense management strategies to control and optimize its costs.

- Value engineering:Reviewing and redesigning products or processes to reduce costs while maintaining or improving quality.

- Vendor negotiation:Negotiating favorable terms with suppliers for raw materials and other goods and services.

- Lean manufacturing:Implementing principles and techniques to eliminate waste and improve efficiency in production processes.

Cost and Expense Forecasting

Knight Company prepares forecasts of future costs and expenses to support financial planning and decision-making.

These forecasts are based on historical data, industry trends, and other relevant factors. They help Knight Company anticipate future cost pressures and make informed decisions about resource allocation and pricing.

FAQ Explained

What types of costs and expenses did Knight Company incur in May?

Knight Company incurred various costs and expenses in May, including raw materials, labor, utilities, marketing, and administrative expenses.

How do Knight Company’s costs and expenses compare to industry benchmarks?

Knight Company’s costs and expenses are generally in line with industry benchmarks, indicating efficient cost management practices.

What cost management strategies has Knight Company implemented?

Knight Company has implemented several cost management strategies, such as lean manufacturing, supplier negotiations, and expense optimization programs.